Ranadive Consultancy Services (RCS) is at the forefront of Industry 4.0 innovation with its research and development division, Yantree Laboratories. Yantree Laboratories is dedicated to developing cutting-edge solutions that leverage the latest technological advancements to help manufacturing industries stay competitive.

RCS’ expertise in Industry 4.0 has enabled us to help our clients improve their manufacturing processes, optimize their supply chain, and enhance their product quality. With our solutions, our clients have been able to reduce costs, increase productivity, and improve customer satisfaction.

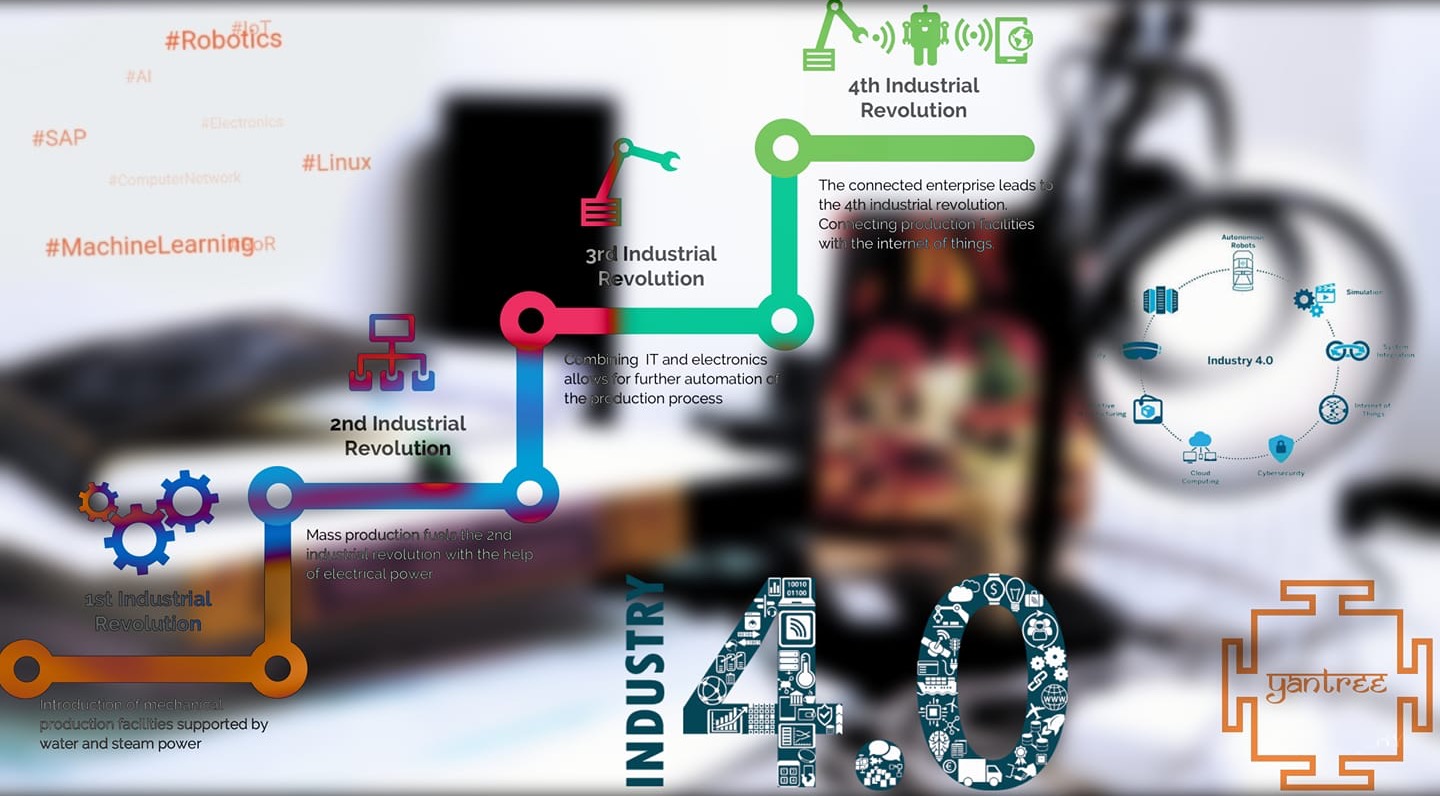

Our capabilities in IoT, AI, ML, Robotics, and 3D printing have helped our clients leverage the latest technologies to gain a competitive advantage in their respective industries. We help our clients to identify opportunities to optimize their manufacturing processes, reduce waste, and improve quality. Our solutions are tailored to meet our client’s unique needs, enabling them to achieve their goals and objectives.

In conclusion, Industry 4.0 is the future of manufacturing, and RCS’ expertise in IoT, AI, ML, Robotics, and 3D printing can help clients take advantage of this new revolution. Our solutions are designed to help clients optimize their manufacturing processes, reduce costs, and enhance their product quality. With our expertise, we can help clients stay ahead of the competition in today’s fast-paced and rapidly evolving manufacturing landscape.